automatic tapper and drilling machine of drilling bit

Basic Info

Model No.: 116

Product Description

automatic tapper and drilling machine of drilling bit

We are able to offer 2 to 14 adjustable spindle heads choices. It is suitable for large distance requirement and flexible collets and chuck are used. We are able to offer various collet type: JT1 / JT2/JT6/ C-5/ C-9/ C-6/C-12.

Maximum drilling capacity is available from 5.0~12mm. Lowest distance is available from 12.05mm-102mm

Maximum range of centers is available from 75mm~450*600mm

Contact us lch(at)lih-cherng.com.tw for further information.

We are able to offer 8 types of clamping tools

1. C form flexible collet

Advantages: space-saving and can be minutely adjusted between two spindles.

Defect: each flexible collet is used for drill bits or taps uniform in size only for bits or taps in different specs, users need to change the collet

2. JT Drill chuck

Advantages: JT chuck can be used for drill bits and taps in different specs, with no need to be changed

Defect: can be used only when there is maximum space limit between two spindles

3. ER collet

Chuck adjustment range is 1mm; strong clamping force: for universal use.

4. AS adjustable drill spindle

Used for large-bore drilling, this spindle incorporates a mores taper drill, which allows for easy drill spindle length adjustment and easy disassembly of the drill, unlike MT drill spindles which may cause damaging of the drill spindle in the event that the drill is disassembled improperly.

5. FT Floating Drill Spindle (simple floating)

Especially suitable for the tapping of punch-pressed iron plates; provides a 0.5mm floating range to allow for the screw tap to be automatically moved to the hole-processing position by find adjustment.

6. Expansion Tapping Drill spindle (rapid screw tap changing)

It is designed for special-purpose for the tapping of workpieces with different thread pitches: provides wide extension and compensation range. Safety torque device will slip when torque exceeds its limit during processing, preventing the screw tap from breaking so as to damage the workpieces.

7. TR+ER Drill spindle

It is an efficient processing instrument combining the advantages of both the ER collet and the adjustable drill spindle.

8. AS adjustable +MT drill spindle

It is an adjustable + MT drilling spindle is easy to disassemble and adjust the depth of drilling.

Types | Collet size | R.P.M | Max. Drilling capacity (mm) | Lowest distance (mm) | Max. range of centers (mm) | No. Spindle |

T-075 | C-5 | 1:1 | 5.0 | 12.05 | 75 | 2 |

T-108 | C-6 | 1:1 | 6.0 | 18 | 108 | 2 |

T-121 | C-9 | 1:1 | 8.0 | 24 | 121 | 2 |

T-121 | C-12( light) | 1:1 | 10.0 | 27 | 121 | 2 |

T-165 | C-12 (strong) | 1:1 | 12.0 | 33 | 165 | 2 |

D-170 | JT1/JT2 | 1:1.69 | 6.0 | 38 | 170 | 2 |

D-176 | JT2/JT6 | 1:1.35 | 9.0/12 | 38/46 | 176 | 2 |

it is a four spindle adjustable head.

it is suitable for small distance requirement.

flexible collet and chuck is used.

116

coller type: C-6

R.P.M: 1:1.35 Multiple Spindle Head

maximum drilling capacity: 6.0

lowest distance: 18mm

Max.range of centers: 100mm

Spindle: 2-4

Lih Cherng is specialized in 9 series, including pressure control valves, flow control valves, directional control valves, modular control valves, logic valves, solenoid check valves, hydraulic gear pumps, piston and Vane Pump Series.

Our renowned valves and flow controls enable engineers to design systems that are easier to install, more efficient, and longer lasting in even the harshest environments.

We offer a unique combination of proven technology and innovative design that translates directly into reliable performance and enhanced uptime. Whether you need a single component, a custom-engineered solution, or anything in between, Lih Cherng is the partner of choice for mobile and industrial applications that simply have to work.

Lih Cherng works with suppliers who deliver the best quality, value and service at the most competitive cost. Our suppliers are innovative and dedicated to driving continuous improvement in their operations.

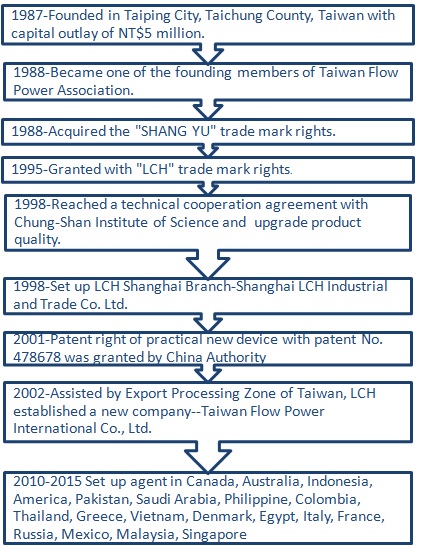

Company History:

Product process:

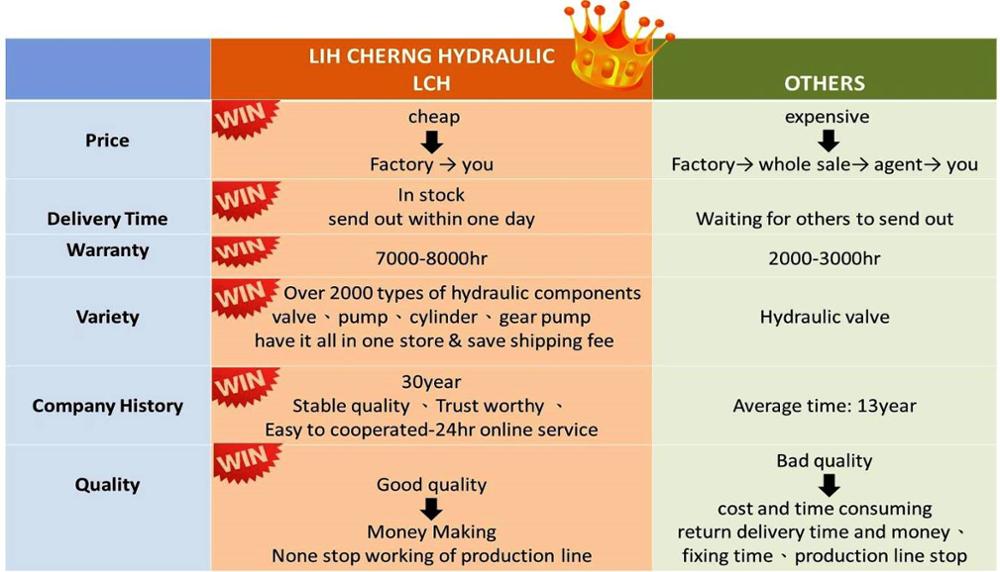

Why Choose Us:

- 30+ years experiecne

- D&B certificate

- R&D team OEM/ODM service

- Best beofre and after customer service

- 24 hours online service

- 100% Made in Taiwan

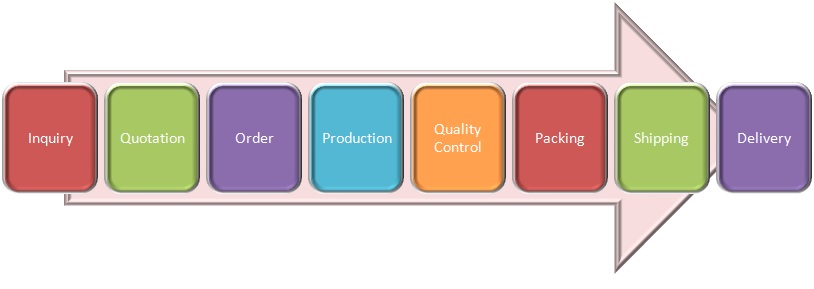

Order Process:

- inquiry from customers

- offer proforma quotation to customers

- recieve Proforma order from customer

- start production

- quality control after production completed

- packing

- shipping

- delivery to customers

Packing:

All goods are packed with plastic bag in carton material package.

Shipping:

1. For small quantity, shipment is prefered to shipping with express by TNT, FEDEX, DHL,OCS, EMS, or UPS to meet your deadline worldwide basis.

2. For regular mass production, shipment could be shipped either by sea or air. Pleaes inform us your requirements, so then we could offer available options for you to save budget.

Q.How to request a manufacturing quote from LCH?

A.Give us a call or send us an E-mail (lch at lih-cherng.com.tw) with your purchase request.

Q.What are your quality control procedures?

A.LCH is equpped with high-tech, advaned cmputerized and self-inspection machineries, manufactures thousands of different parts in house to ensure the built-in quality and dependable performance. This is the reason hy LCH is recognized as on the world class quality level.

Q.How are orders packed and shipped?

A. Depends on customers' orders. All goods are packed with a plastic bag with an outer carton and a wooden pallet( fumigatation).

Q. Could LCH offer OEM service?

A.Yes. LCH is able to offer OEM with customers' brand name and trademark onto the product.

Q.Do LCH products come with a warranty?

A.Yes.LCH offer 1-year product life guarantee without abusive usage on all purchases which begins with the bill of lading.

Hydraulic components such as hydraulic valve, Solenoid Valve, hydraulic directional valve, oil pump, hydraulic Gear Pump, gear pump, electric motor, electrical motor, ac motor, hydraulic cylinder, cylinder, hydraulic power pack, hydraulic power unit, hydraulic power station, sandwich check valve, flow control valve, hydraulic pump and chemical pump are able to used in injection molding machine, full automatic compacting press, die casting machine, hydraulic excavator, garbage truck,machine center, and rubber press machines.

keyword search Lih Cherng Hydraulic Co., Ltd, or add my what's app ID+886920438696

We offer 24 hours online customer service for you

Our Product Categories:

click on each catagories below that you are interetsed in for more references.

Pressure control valve | Flow control valve | Directional control valve | Sandwich plate valve |

Hydraulic gear pump | Hydraulic Vane Pump | Hydraulic accessories | Hydraulic cylinder |

Spindle head device | Electric ac motor | Snap & Carabiner |

Lih Cherng Hydraulic supplier is your best choice!

Leave us a msg and we will offer a Special Discount for you !!!↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓↓

Product Categories : More Products > Spindle Head