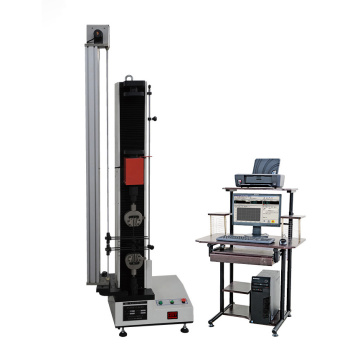

Computer Control Tension Testing Machine

Basic Info

Model No.: WDW

Product Description

Application of computer control tension testing machine:

The software features of this computer control tension testing machine include graph comparison, point tracing facility. This user friendly software has real time graph, it can Extensive graphics on screen for curve plotting, magnification and zooming. Software packages for shear, bend, torsion, rubber, textile testing etc. Custom built application software to suit customer requirements. We are providing a qualitative range of Universal Testing Machine. Equipped with many qualities, this machine is serving various industries. Servo controlled electronic universal testing machine can be attained at market leading prices. We are a leading Manufacturer of electronic universal testing machine, front open cross head universal testing machine, universal testing machine, computerized universal testing machine and servo controlled universal testing machine. We are a renowned and customer-oriented company, which is engaged in delivering a comprehensive range of electronic universal testing machine. It is equipped with electronic digital display for load and elongation.

Loading frame :

The base has a hydraulic cylinder at its center and two main screws at both ends. The middle cross head is mounted on screws through main nuts. The middle cross head can be moved up or down through chain transmission and geared motor to adjust the initial tensile/compression clearance. Inside base of machine, hydraulic cylinder is tested in which piston is placed on the piston, rests an assembly of upper, lower cross head and two columns.The individually lapped cylinder piston assembly ensures smooth axial force with minimum friction.Control panel :

Hydraulic circuit it consists of hydraulic power pack which has a directly driven radial plunger pump which gives continuous non pulsating flow of oil pressure up to 250bar a pressure compensated needle type flow control valve is obtained with help of valves. Optionally this can be controlled form electronic system.

Loading rate / straining rate control :

This is superfine controlling system which controls loading rate / straining rate as per commands from electronic machine control system. FINE UTM Software can send loading rate / straining rate to electronic system for fully automatic testing.Load Measurement System :

The oil pressure in the main cylinder is also transferred to an electronic pressure transducer which gives proportionate signal to electronic unit. Both the motors for hydraulic operation and cross head motion are controlled by buttons on electronic control system and they have interlocked to prevent simultaneous working of motors. The electrical panel is housed in control panel. Displacement measurement is carried out by means of a rack and pinion on rotary encoder. Encoder signal is fed to electronic system to get displacement.Operation :

Tension test is conducted by gripping the test specimen in the upper and middle cross head. Compression, Bending, Transverse, Shear and Hardness tests are conducted between the middle and lower cross head by using appropriate fixtures. The rapid adjustment of middle crosshead facilitates easy fixing of tensile / Compression specimens of different lengths. Hydraulic controls are through hand operated valve, ergonomically placed for ease of control. Optionally valves can be controlled form electronic control system.Adequate safeties for over load and over travel are incorporated and emergency switch is provided.Accuracy & Calibration :

Every machine is calibrated in accordance with procedure laid down international standard.Computerized universal testing machines comply with grade Aof BS 1610-1964 and Grade 1.0 of IS 1828-1991. An accuracy of ± 1% guaranteed from 2% to 100% of capacity of the machine. In the computerized UTM, the computer is an integral part of the entire system and not just on ADD ON feature. This puts a lot of power and versatility into the hands of the operator and makes the system much more self contained than usual, as it includes many functions usually only available as additional (often expensive) optional features.Standard: ASTM, ISO, DIN, GB and other international standards.

Main Technical Parameters:

| Model | WDW-1 | WDW-2 | WDW-3 | WDW-5 |

| Max. load | 1KN | 2KN | 3KN | 5KN |

| Structure | Single column double spaces | |||

| Control method | computer control | |||

| Load accuracy | 1 class | |||

| Load range | 2%~100%F·S/0.4%-100% FS | |||

| Displacement Resolution | 0.01mm | |||

| Test speed | 0.05-500mm/min(can be customized) | |||

| Tensile space | 600mm(can be customized) | |||

| Compression space | 600mm(can be customized) | |||

| Power supply | AC220V±10%,50Hz(can be customized) | |||

| Grips | Wedge type, plate type and other grips as consumer`s demand | |||

| Dimension | 425*400*1315mm | |||

| Weight | 90kg | |||

More pictures of our testing machine

Product Categories : Electronic Universal Test Machine > Computer Control Utm